Anúncios

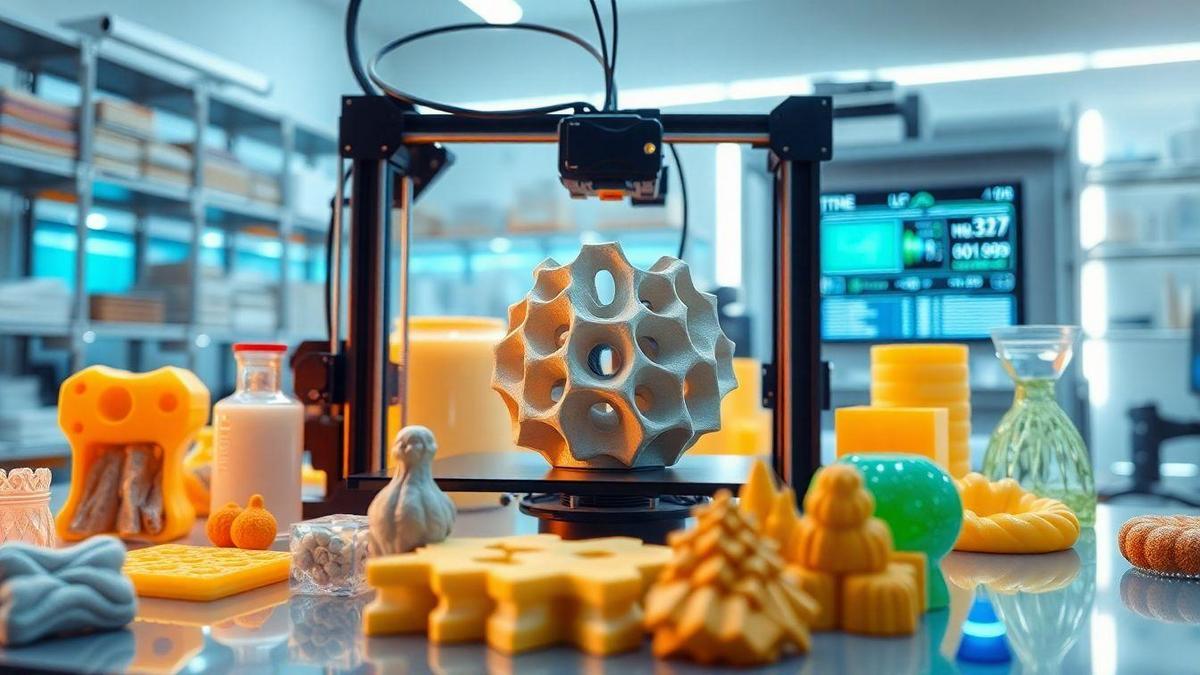

4D printing is an evolution of 3D printing that introduces the ability for structures to adapt to environmental stimuli such as light, temperature, or humidity. With this innovation, smart materials can be designed to change shape or function, creating dynamic and adaptable systems. The 4D printing technology opens up new possibilities in areas such as healthcare, construction, and robotics, bringing innovative solutions to various sectors.

This technology uses materials that respond to specific stimuli, enabling the creation of objects that can undergo programmed transformations. In addition to expanding the functionality of products, it also contributes to more sustainable practices by reducing waste and the need for additional components. 4D printing represents a revolution in the way we design and manufacture objects in the future.

Anúncios

Understanding Smart Materials in 4D Printing

Smart materials are the foundation of 4D printing, designed to respond to environmental stimuli. These materials can change their physical properties when exposed to variations in temperature, humidity, or light. The combination of materials like shape-memory alloys or hydrogels allows printed objects to respond to stimuli in a programmed way, changing shape as needed.

By applying these materials, it is possible to create devices and structures with adaptive properties. This allows them to adjust to different conditions or needs over time. In areas such as medicine, this could lead to the creation of more comfortable and efficient implants that adapt better to the human body.

Additionally, smart materials can help improve energy efficiency. For example, in buildings, adaptive materials can adjust their shape or thermal insulation based on weather conditions, optimizing energy use. The flexibility of these materials is a key feature that opens up new opportunities for innovation in design.

These materials can also be designed to have a smaller environmental impact. The possibility of creating more efficient and durable objects that do not require frequent replacements helps reduce resource waste and production impact. In this way, 4D printing not only improves product functionality but also contributes to more eco-friendly manufacturing practices.

The Role of Responsive Polymers

Responsive polymers play a crucial role in 4D printing due to their ability to change shape when exposed to external stimuli. These materials can swell or shrink in response to changes in temperature or humidity, allowing the creation of dynamic structures. This property makes polymers ideal for a variety of applications, from manufacturing medical devices to creating automation systems.

The adaptability of responsive polymers is an essential characteristic for 4D printing, allowing final products to intelligently respond to their environment. This ability can be used to develop more functional products with a higher degree of customization, meeting the specific needs of different industries and applications.

These polymers can also be combined with other materials to create composites with even more advanced properties. For example, by combining responsive polymers with fibers or metals, it is possible to produce materials that are stronger and more efficient. This opens up new possibilities for creating more durable and versatile products.

In the field of robotics, responsive polymers allow the development of more flexible and adaptable systems. Robots capable of changing their shape or rigidity as needed can perform complex tasks and quickly adjust to different environments or working conditions. This represents a significant advancement for robotics, expanding its potential applications.

How Does 4D Printing Work and Material Reconfiguration with Environmental Stimuli?

4D printing is an innovative advancement that extends the principles of traditional 3D printing by introducing the dimension of time. This technology enables the creation of structures that can change their shape or properties in response to environmental stimuli such as temperature, humidity, or light. The concept of 4D printing revolves around the use of smart materials that can undergo programmed transformations, allowing the production of dynamic and adaptive systems. These systems can perform functions that were previously unattainable with static materials, leading to a new wave of applications across various fields, including healthcare, robotics, and construction.

The 4D printing process involves the integration of specific materials that have the ability to respond to external stimuli. These materials are often designed to achieve specific responses, such as bending, twisting, or expanding when exposed to certain conditions. By carefully designing the geometry and composition of the printed object’s material, researchers can create complex structures capable of self-assembly or self-repair. This not only enhances the functionality of the printed items but also contributes to more sustainable manufacturing practices by reducing waste and the need for additional components.

Advantages of 4D Printing and Material Reconfiguration with Environmental Stimuli

The advantages of 4D printing and material reconfiguration are numerous and significant. One of the key benefits is the ability to create adaptive structures that can change their shape or function in real-time. This capability opens up new possibilities for design and engineering, enabling the development of products that can respond to their environment, increasing their usability and efficiency. For example, in architecture, buildings can be designed to adjust to weather conditions, optimizing energy consumption and occupant comfort.

Another advantage is the potential to reduce manufacturing costs and material waste. Traditional manufacturing processes often require multiple components and complex assembly, leading to high costs and environmental impact. With 4D printing, products can be designed as unique entities that transform as needed, minimizing the number of parts and resources required. This simplified approach benefits manufacturers and contributes to more sustainable practices by reducing the carbon footprint of production.

Additionally, 4D printing offers the possibility of creating self-repairing materials. These materials can automatically repair themselves when damaged, significantly extending the lifespan of products and reducing the need for replacements. This self-repair capability is particularly valuable in industries such as aerospace and automotive, where safety and reliability are paramount. By incorporating self-repair properties, manufacturers can increase product durability and reduce maintenance costs.

Finally, 4D printing promotes innovation in various sectors, including healthcare. The ability to create responsive medical devices that adapt to patients’ needs could lead to better treatment outcomes and personalized care. For example, implants that can change shape to better fit the body or drug delivery systems that release medication in response to specific biological signals are just a few examples of how 4D printing could revolutionize healthcare.

How to Use 4D Printing and Material Reconfiguration with Environmental Stimuli

Understanding Smart Materials in 4D Printing

Smart materials are the foundation of 4D printing technology. These materials have unique properties that allow them to respond to environmental changes. By incorporating smart materials like shape-memory alloys or hydrogels, designers can create objects that undergo significant transformations in response to stimuli. This adaptability can be harnessed in various applications, from medical devices to consumer products.

Exploring Shape-Shifting Technology

Shape-shifting technology is a fascinating aspect of 4D printing. By utilizing specific geometric designs and material properties, objects can be programmed to change their shape when exposed to environmental triggers. This technology has the potential to revolutionize industries by enabling the creation of products that can transform to meet users’ needs, enhancing functionality and adaptability.

The Role of Responsive Polymers

Responsive polymers play a critical role in 4D printing. These materials can undergo significant changes in their physical properties when subjected to external stimuli. For example, certain polymers can swell or shrink in response to temperature changes, enabling the creation of dynamic structures that can adapt to their environment. This responsiveness enables the development of innovative applications in fields like robotics and healthcare.

Benefits of Adaptive Structures

Adaptive structures are a key advantage of 4D printing. These structures can adjust their shape or properties based on environmental conditions, leading to improved performance and efficiency. In architecture, for instance, adaptive structures can optimize energy use by adjusting to weather conditions, while in robotics, they can improve maneuverability and functionality. The ability to create adaptive systems represents a significant advancement in design and engineering.

Innovations in Self-Assembly Materials

Self-assembling materials are an exciting area of research within 4D printing. These materials can spontaneously organize themselves into complex structures without the need for external intervention. This capability could lead to significant advancements in manufacturing and construction, allowing for the creation of intricate designs that would be challenging to achieve with traditional methods. The potential for self-assembly opens up new avenues for innovation across various industries.

Sustainable Manufacturing Practices in 4D Printing

Sustainable manufacturing is a critical consideration in today’s world, and 4D printing offers promising solutions. By using smart materials and minimizing waste through efficient design, 4D printing can contribute to more sustainable production processes. The ability to create products that adapt and self-repair further enhances sustainability by reducing the need for replacements and repairs. Adopting 4D printing technology could lead to a more eco-friendly approach to manufacturing.

In conclusion, the use of 4D printing and material reconfiguration with environmental stimuli presents a wealth of opportunities for innovation and efficiency across various sectors. By harnessing smart materials and adaptive structures, designers and engineers can create products that are not only functional but also responsive to their environment. This technology has the potential to revolutionize manufacturing practices, improve sustainability, and elevate quality of life through advanced applications in healthcare, construction, and beyond.

Did You Enjoy Learning About 4D Printing and Material Reconfiguration with Environmental Stimuli?

Learning about 4D printing and material reconfiguration with environmental stimuli reveals a fascinating world of possibilities. This innovative technology is poised to revolutionize various fields by introducing dynamic and adaptive systems that respond intelligently to their surroundings. The potential applications are vast, ranging from healthcare to architecture, making this an exciting field to explore further.

As you dive deeper into the realm of 4D printing, you will discover the countless ways it can enhance our lives and the environment. The fusion of smart materials and responsive designs offers a glimpse into a future where products are not only functional but also capable of evolving to meet our needs. Embrace the journey of discovery in this transformative field!

Frequently Asked Questions

What is 4D printing and how does it work?

4D printing is a technology that uses special materials. These materials can change shape with environmental stimuli such as temperature or light.

What materials are used in 4D printing?

Common materials include polymers and fibers. They have the ability to adapt and change as needed.

How can 4D printing help the environment?

This technology can reduce waste. Materials that adjust can be more efficient and durable.

What are the challenges of 4D printing?

We still need to improve accuracy. Additionally, large-scale production is a challenge to overcome.

Where can I see 4D printing in action?

You can find 4D printing in research and development. Some universities and companies are experimenting with this technology.